Recently, the commissioning ceremony for the 12-inch integrated circuit analog specialty process production line project (Phase III) at Yuexin Semiconductor was grandly held in Guangzhou Development Zone. This marks the official production launch of Yuexin Semiconductor's Phase III project, as well as the successful deployment of the custom-designed new air-handling units (MAUs) by Tongfang Ruifeng for the project. Following the successful implementation of the first and second phases, Tongfang Ruifeng once again provides professional environmental support for Yuexin Semiconductor’s production process.

The total investment for Yuexin Semiconductor’s Phase III project is 16.25 billion yuan, covering 280,000 square meters with a building area of 450,000 square meters. The project aims to create an industrial-grade and automotive-grade analog specialty process platform, utilizing 180-90nm process technology. The products primarily cater to power device chips for power electronics and automotive electronics, signal chain chips, power management chips, microcontroller chips, image sensors, and more. The phase is expected to add a monthly production capacity of 40,000 wafers, with an annual output value of approximately 4 billion yuan.

Yuexin Semiconductor, founded in December 2017, is a 12-inch semiconductor manufacturing company focusing on analog chips. It operates the first 12-inch chip production line in Guangzhou and is the first in Guangdong Province and the Greater Bay Area to enter mass production with a 12-inch chip platform. As a key player in Guangdong's strategy to develop China’s integrated circuit “third pole,” Yuexin Semiconductor plays an essential role in driving the development and high-endization of the province's integrated circuit industry chain. The project is being built in three phases, and once fully completed, it will achieve a high-end analog chip manufacturing capacity of nearly 80,000 12-inch wafers per month.

Precision and Reliability: The Core of Semiconductor Production

A constant temperature, constant humidity, clean, and safe production environment is fundamental to semiconductor production. Stable, reliable, efficient, and energy-saving air conditioning equipment is crucial for ensuring the efficiency of process air conditioning systems. Tongfang Ruifeng, with 15 years of experience in designing and manufacturing custom air conditioning products, has tailored air-handling units (MAUs) and other HVAC products for Yuexin’s first, second, and third-phase projects. After several seasons of stable operation, these products have earned the trust of users.

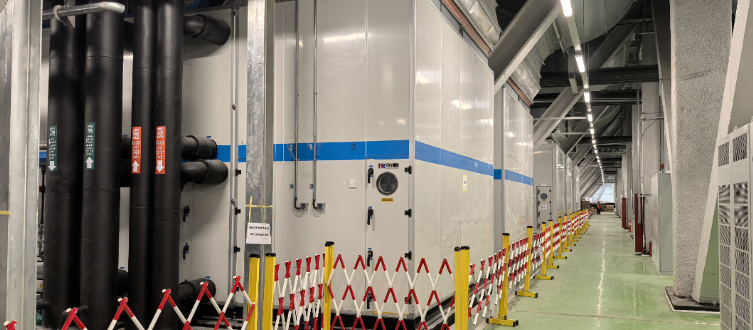

The newly designed MAU units for the semiconductor industry are specifically customized by Tongfang Ruifeng to meet the production environment requirements for semiconductors. In addition to basic functions such as multi-stage dust filtration, cooling, dehumidification, reheating, heating, humidification, and harmful gas removal, Tongfang Ruifeng excels in key technical details such as unit strength assurance, thermal bridge insulation, sealing, and corrosion resistance of components. This focus ensures reliable operation and guarantees the long-term success of the product. Notably, the MAUs for this project feature Tongfang Ruifeng's proprietary "high-strength PU board without thermal bridges" structure, which offers superior structural strength, sealing performance, and exceptional insulation and thermal bridge prevention capabilities—far surpassing the performance of current common frame structures. This design is especially suited for applications in extreme conditions such as high air volume, large temperature differentials, and outdoor installations.

Tongfang Ruifeng's proprietary thermal bridge-free structure has been successfully applied in industries such as low-temperature food processing, tobacco, semiconductor chip manufacturing, and photovoltaic new energy. These units have been well received by users for their stable and excellent performance and have also passed national-level testing with a 140,000 CMH high-airflow unit certification.

Craftsmanship and Excellence: Together, We Achieve Greatness

During the installation, commissioning, and acceptance of the MAUs for Yuexin Semiconductor’s Phase III project, Tongfang Ruifeng collaborated closely with all participating units to overcome numerous challenges and ensure the project was completed on time and to a high standard. This has resulted in the satisfaction of the customer’s "repeated" trust.

The future is now, and we move forward together. Tongfang Ruifeng will continue to uphold the principles of "Excellence, Quality, Innovation, and Creation" and strive for perfection and continuous innovation. We remain dedicated to providing high-quality products and excellent services for industries, including the semiconductor sector, contributing to the development of new productive forces and supporting China’s high-quality industrial growth!